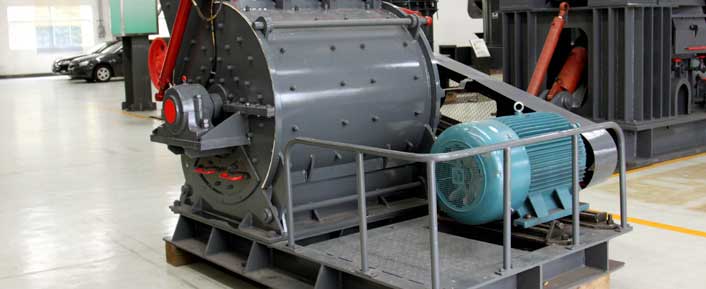

Hammer Mill

hammer mill is my company R & D and manufacturing of 0-3MM used in the production of coarse powder of a new generation of mill. The machine follows a part of the working principle of the crusher, to make up for the shortcomings of traditional milling machine product particle size range, become the core equipment in the production of coarse powder particles

Detailed introduction

- 1. High crushing ratio of production capacity

- 2. Stable performance with uniform particle size

- 3. Low investment cost and convenient management

- 4. Has the advantages of simple structure and convenient repair

| Name & Model | HM4008-75 | HM4012-90 | HM4015-132 | |

|---|---|---|---|---|

| Rotor diameter(mm) | 750 | 900 | 1150 | |

| Rotor length(mm) | 800 | 1200 | 1500 | |

| Rotor speed(rm) | 800-1000 | 800-1000 | 550-800 | |

| Feeding size(mm) | 320×930 | 400×1200 | 500×1500 | |

| Max feed size(mm) | <30 | <40 | <50 | |

| Discharge size(mm) | 0-3 | 0-3 | 0-8 | |

| Theory processing capacity(th) | 8-15 | 15-40 | 40-70 | |

| Motor | Model(Standard) | Y280S-4 | Y280M-4 | Y315L2-6 |

| Power(kw) | 75 | 90 | 132 | |

| Rotate speed(rm) | ||||

| Hammer number(pcs) | 18 | 32 | 32 | |

| Dimension(L×W×Hmm) | 2130×1665×1610 | 2840×2100×2020 | 3720×2650×2540 | |

[ Feed size]: 30-50mm

[Capacity]: 8-70T / h

[Applications]: widely used in metallurgy, mining, chemical, cement, coal, construction, sand, refractories, glass and ceramics and other industrial and mining enterprises, engaged in materials broken and minor operations.

[Applicable materials]: suitable crushing limestone, calcite, dolomite, barite, talc, calcium carbonate, gypsum, bentonite and the like.

The working principle of hammer crusher

Crusher (hammer crusher) is a kind of impact rotor with ring hammer crusher. Ring hammer not only can rotate following the rotor, but also Rao hammer pin shaft rotation. The material into the crushing machine, in the crushing cavity by the high-speed rotation of the rotor with ring hammer impact crusher, the material being broken at the same time to obtain kinetic energy from the ring hammer, rushed to the crushing plate at high speed by two times, crushing, and then fall on the sieve plate, collisions between shear, extrusion, grinding ring hammer and the material and the material, the material to be further broken, and discharged out of the machine through a sieve. Not broken debris from ring hammer into metal collector, clear regularly by the operating personnel. Hammer crusher strict requirements on water, using the hammer force broken coal, following a sieve plate is greater than the required to continue the crushing, screening into the boiler is less than.